Technologies For Innovation

SERVICES

After-sale service

+86 10-57374441

27

03

RUISHENBAO Ultra-high Pressure System Is Applied in Metallurgical Industry-- Ferrosilicon

Ruishenbao Analytical (Shanghai) Co., Ltd

Key word: Ferrosilicon beads, XRF,

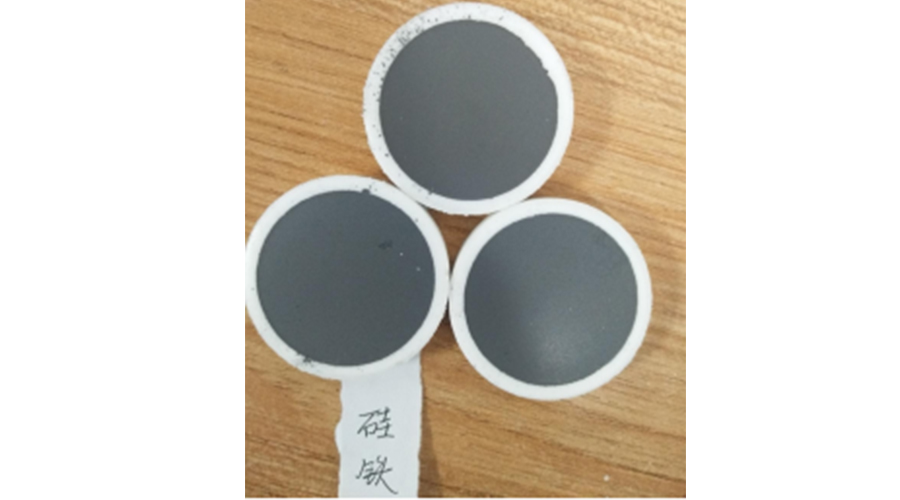

Ferrosilicon is little, but indispensable in smelting iron and steel. In iron and steel industry, ferrosilicon plays quite an important role in iron alloy, steel smelting and casting, which are the largest ferrosilicon consumption fields. In iron and steel industry, the production of 1T iron needs 75% ferrosilicon for 3-5kg. The wet analysis, commonly used in China, whose complex sample preparation needs time, energy and pollutes environment, can not meet requirements of modern smelting enterprises on rapid and accurate detection data and environment protection. With the advantage of rapidity and accuracy well meeting analysis requirements, XRF is an ideal analysis method of multiple metal elements. Ferrosilicon is the iron alloy, smelt by electric oven with raw materials such as coke, steel chips and silica. Due to high hygroscopicity and poor adhesion, ferrosilicon is hard to produce qualified beads by “low-pressure ” pellet presses. However RUISHENBAO UHPS ultra-high pressure system produces sample beads successfully which can satisfy XRF analysis requirements.

2. Sample preparation equipment and tools

1)Equipment

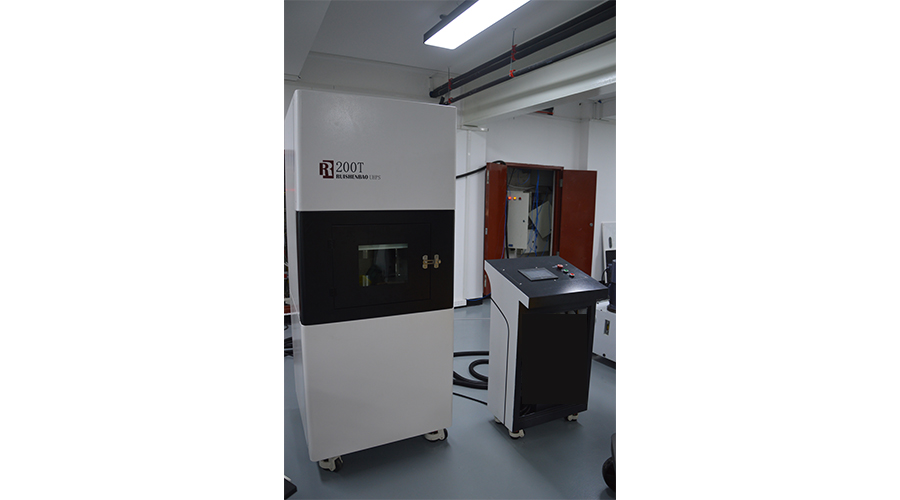

RUISHENBAO ultra-high pressure system:UHPS

2)Sample cup

Polyethylene sample cup (PE cup in short)

3)Grinding equipment

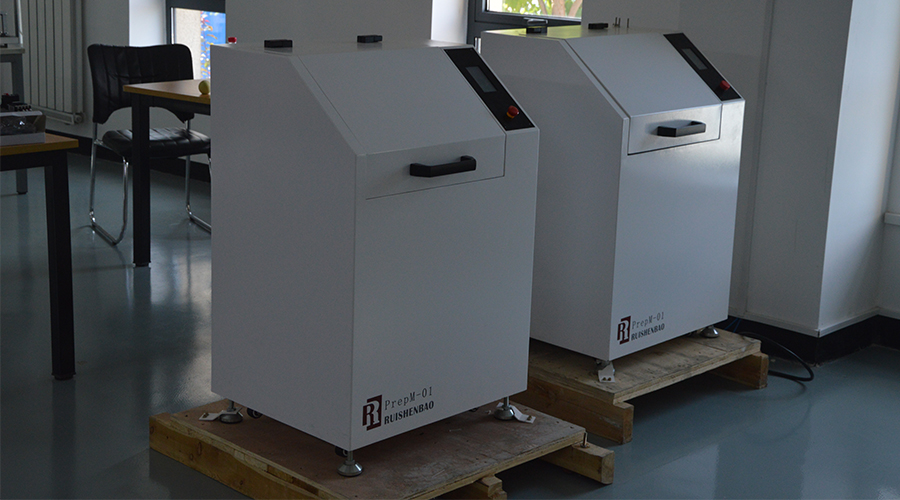

PrepM-01 vibratory disc mill

3. Sample preparation

Fill the chromium steel grinding jar of PrepM-01 with 3/1 ferrosilicon, and start the mill at 1200rpm. After grinding for 3min with particles less than 200 mesh, pour out samples for backup.

Flatten samples on PE cup (the samples just fill the entire mold without more or less amount), put the mold gently into UHPS sample table slot to avert spattering (First make sure the sample table is clean). Cover with tungsten carbide pad, press it into the slot, and ensure the its upper surface not higher than the mold surface. Then close the protection door and start the program. Set UHPS parameters of the pressure at 1600KN, pressure holding for 30s, extraction for 6s. Then click to start and begin the automatic pressure holding, followed by automatic extraction. After clicking START again to eject the sample, remove the mold and take out the sample.

The sample can be directly produced by RUISHENBAO UHPS ultra-high pressure system without any need of preliminary handling or chemicals. Besides, it takes just several minutes to produce a bead, and it is economic, convenient and environment-friendly.

+86 10-57374441

+86 136 8188 9743

info@ruishenbao.com

Whatsapp:+86 13681889743

Skype:+86 13681889743

Room1006,No.280,ShangZhongXiLu,Xuhui district,ShangHai,200237,P.R.China

+86 10-57374441

+86 136 8188 9743

info@ruishenbao.com

Whatsapp:+86 13681889743

Skype:+86 13681889743

Room1006,No.280,ShangZhongXiLu,Xuhui district,ShangHai,200237,P.R.China