Technologies For Innovation

SERVICES

After-sale service

+86 10-57374441

15

12

RuishenbaoRuishenbao liquid nitrogen freezing mill for grinding

Ruishenbao Analytical (Shanghai) Co., Ltd

Key word: frozen grind, cryogrinding,

Analysis of aquatic products sample treatment has always been a difficult problem for inspection research and customs institutions. At present, the existing frozen grinding machine in the market usually processes a small amount of samples. However, there is no unified plan for how to select and which parts to select, so the test results are naturally greatly affected. The liquid nitrogen frozen grinding machine of Ruishenbao Analysis Technology (Shanghai) Co., Ltd. is provided to solve the problem of integrated grinding of bread crab according to the requirements of a customs technical center.

1). Grinding equipment

Cryogenic Mill with Closed Liquid Nitrogen (LN2) Auto-fill: LPM-01

2). Grinding jar

Matching 2.1L food-grade alloy grinding tank

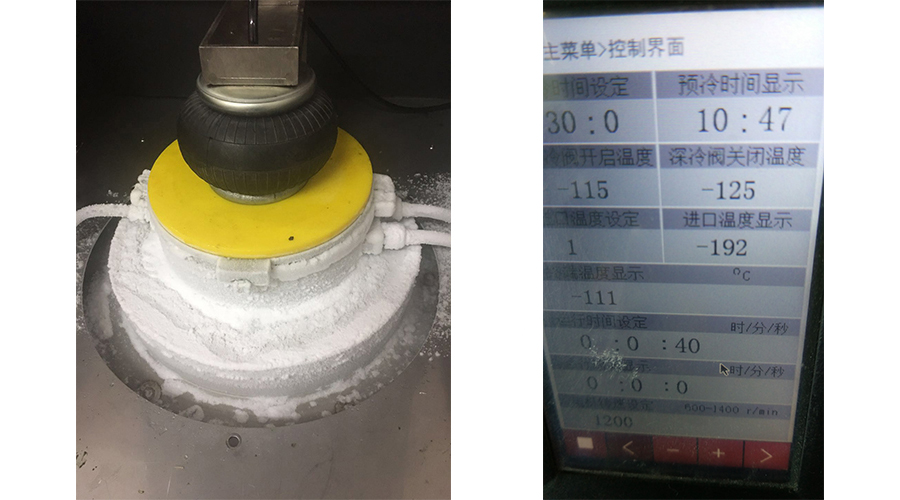

Cut the sample into pieces with scissors (you can put it into a grinding tank), and it is filled into the frozen grinding tank. place the frozen grinding tank in the correct working position. Adjust the pressure head of the grinding tank to the correct position. Click the“ Head on“ button above the operation screen. With the head in place and the freeze grinding tank pressed, close the operating cover of the freeze mill grind workshop. Click on the parameter interface, And set the parameter as: Precooling for 20 minutes (Fully freezing abrasive tools and samples in advance can appropriately reduce the precooling time), Cryogenic valve opening temperature is -115℃,the closing temperature is -125℃,grinding time is 40s,rotate speed is1200r/min.

Open the liquid nitrogen tank outlet valve, Click the device start button to start the device. When the equipment is finished, open the freeze grinder workshop, Click the press head close button on the operation screen to open the frozen grinding tank and take out the sample. Clean the frozen grinding tank, close the outlet valve of liquid nitrogen tank, close the outlet valve of air compressor, as well as the air compressor electromechanical source, and close the frozen grinding electromechanical source.

The Ruishenbao frozen grinder can be used in large volumes to process soft, temperature-sensitive samples with high fat content or brittle at low temperatures, Such as animals and plants or a full range of food solutions. It makes the experiment more convenient and fast, saves a lot of manpower and material resources, and has high application potential.

+86 10-57374441

+86 136 8188 9743

info@ruishenbao.com

Whatsapp:+86 13681889743

Skype:+86 13681889743

Room1006,No.280,ShangZhongXiLu,Xuhui district,ShangHai,200237,P.R.China

+86 10-57374441

+86 136 8188 9743

info@ruishenbao.com

Whatsapp:+86 13681889743

Skype:+86 13681889743

Room1006,No.280,ShangZhongXiLu,Xuhui district,ShangHai,200237,P.R.China