Technologies For Innovation

SERVICES

After-sale service

+86 10-57374441

17

12

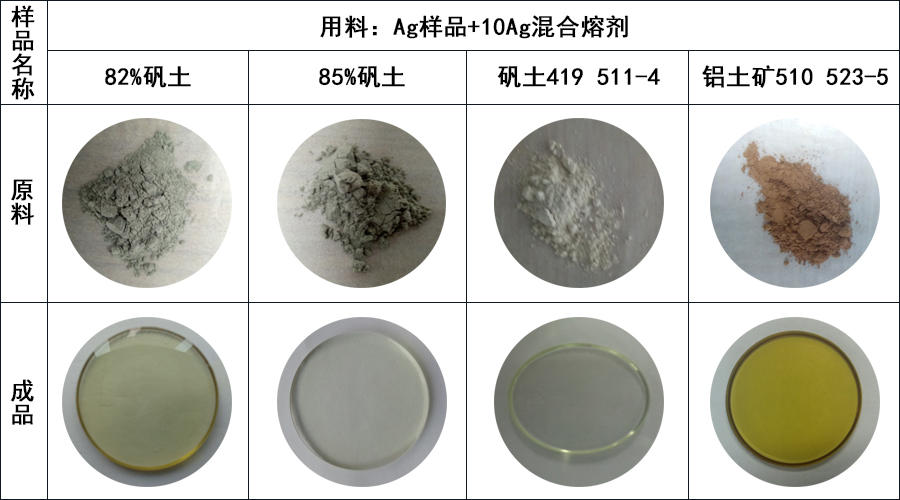

Bauxite samples prepared by Ruishenbao High Frequency Induction Fusion

Ruishenbao Analytical (Shanghai) Co., Ltd

Key word: High, Frequency, Induction, Fusion,

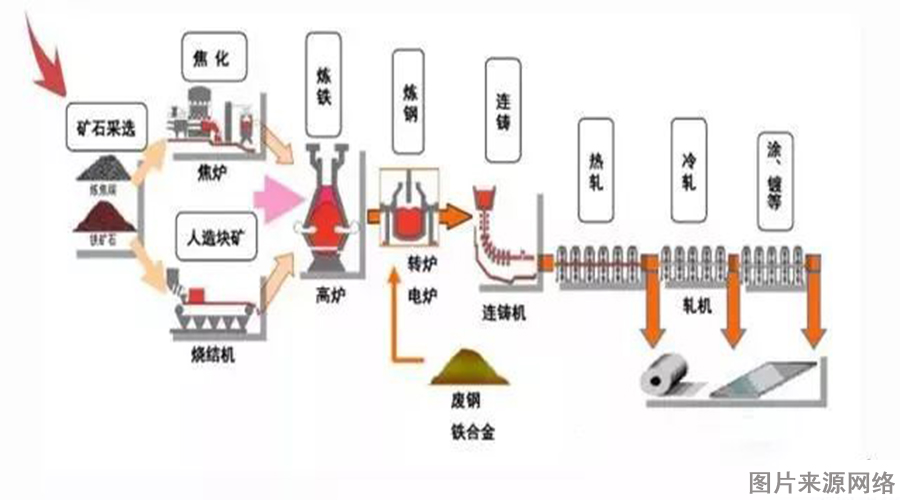

Bauxite is a refractory clay and bauxite that contains high iron content. is composed of aluminum hydroxide or aluminum oxide containing water. It is white, grey or dark grey.Similar in appearance to clay, it is generally lumpy. It is an important raw material for refining aluminum. Its composition and chemical composition is basically the same as that of refractories bauxite, and the Fe2O3 content is generally greater than 10%. It is mainly used as flux for steelmaking in open hearth furnace. It works together with limestone fluorite as slagging agent and is good for removing nodulation on furnace wall. Due to the large variety of bauxite samples, different sources, large variation in the content range of each element, and large production volume, it is necessary to quickly order the content analysis. A large steel enterprise analysis and testing research center used The new high frequency melting furnace of Ruigenbao FHC-00 to prepare samples that meet the requirements

2.1. Equipment :

High Frequency Induction Fusion: FHC-00

2.2. sample:

The customer provided samples and named them as: bauxite 418 510-3, bauxite 419 511-4, bauxite 551 523-5, clay 413 505-1, clay brick 413 507-2-1.

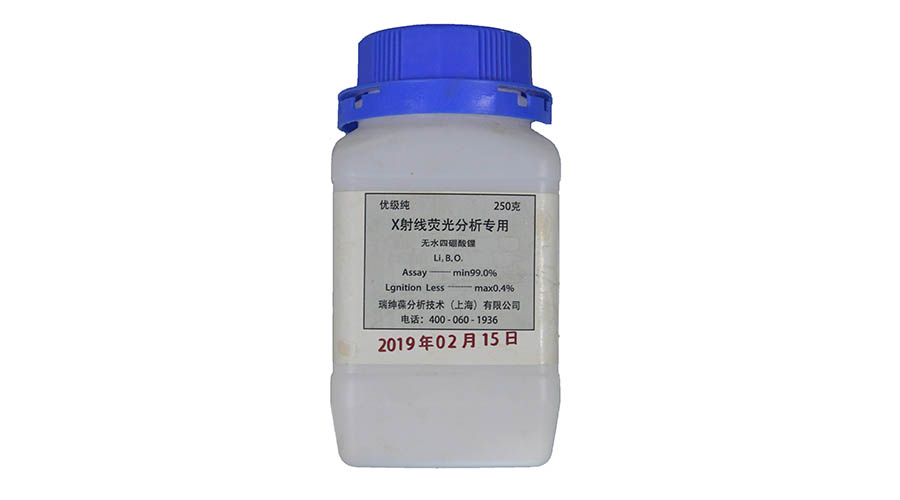

2.3.flux:

Anhydrous lithium tetraborate Li2B4O7,Lithium bromide solution(30%).

2.4. Platinum crucible:

Pt/Au: 95/5

0.7g of the sample was mixed with 7g of lithium tetraborate and put into platinum gold crucible, add 7 drops of LiBr solution. the prepared sample is loaded into the crucible frame of the molten prototype. Set melting temperature to 1100 ,The melting time is 5 minutes, the swing time is 8 minutes, the rest time is 10 seconds before dumping and 10 seconds after dumping, and then start running. After the program is completed, the mold containing the sample is taken out and placed on the refractory plate until it is condensed and stripped. Then the sample is labeled and stored in vacuum drying. Some samples are shown in the figure below:

The FHC-00 high frequency induction fusion can rapidly heat up and cool down through high frequency induction heating to improve working efficiency; At the same time, it is equipped with high-precision infrared temperature measuring system to measure temperature in real time and combined with PID temperature control technology to ensure the temperature accuracy and reproducibility (up to ±1℃) during the melting process, which can meet the requirements of rapid glass melting sample making for different samples.

+86 10-57374441

+86 136 8188 9743

info@ruishenbao.com

Whatsapp:+86 13681889743

Skype:+86 13681889743

Room1006,No.280,ShangZhongXiLu,Xuhui district,ShangHai,200237,P.R.China

+86 10-57374441

+86 136 8188 9743

info@ruishenbao.com

Whatsapp:+86 13681889743

Skype:+86 13681889743

Room1006,No.280,ShangZhongXiLu,Xuhui district,ShangHai,200237,P.R.China