Technologies For Innovation

SERVICES

After-sale service

+86 10-57374441

16

12

Application of Ruishenbao iron remelting machine to cast iron whitening

Ruishenbao Analytical (Shanghai) Co., Ltd

Key word: cast iron, Remelting,

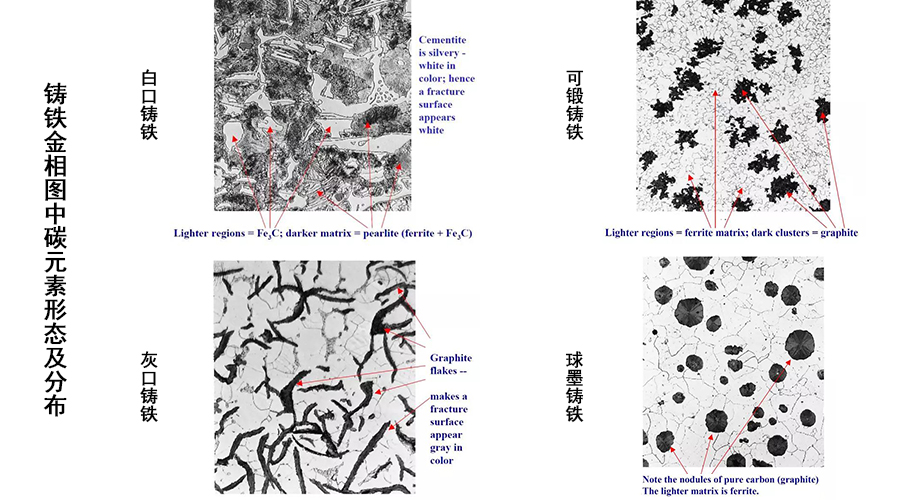

Cast iron is a general term for an alloy consisting mainly of iron carbon and silicon. The toughness and plasticity of cast iron mainly depends on the number, shape, size and distribution of carbon, of which the shape of carbon has the greatest influence. The other properties of cast iron are also closely related to carbon, and the matrix structure is the main factor affecting the compressive strength and wear resistance of cast iron. According to the form of carbon, cast iron can be divided into gray cast iron, white cast iron and hemp cast iron. Among them, white cast iron has fine grain, uniform chemical composition and silvery white fracture, which is suitable for photoelectric direct reading spectroscopic analysis; Gray cast iron and hemp cast iron cannot be accurately measured by spectrometers due to the complex morphology of nonmetallic graphite, coarse grain and uneven chemical composition. Therefore, the conversion of different forms of carbon into the form of combined carbon, namely, the whitening of cast iron, is a necessary condition for the direct reading spectral analysis of cast iron, otherwise the analysis results cannot be guaranteed. Ruishenbao remelting furnace can be used as professional equipment for melting, recasting and whitening treatment of cast iron and other metal material samples. Equipped with a Copper mould, samples of different shapes, such as slimy cutting bar cuttings powder, can be prepared into uniform shape, which can be directly used for spectral analysis.

Ruishenbao: Cast iron remelting machine: CIRF-01

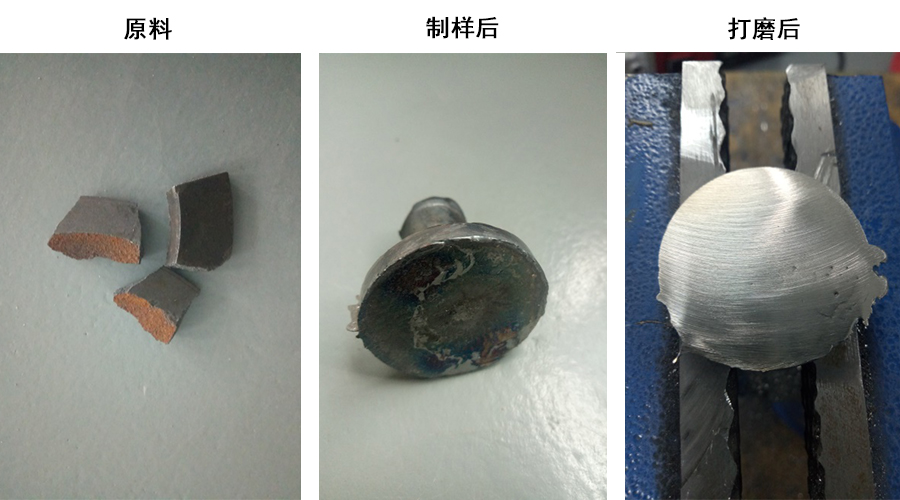

Put about 50g of cast iron into the crucible, The current was set as 165A melting for 10min and then adjusted to 380A melting for 10min, Manually control the external rocker to control the rocking and observe the sample through the observation hole until complete melting (higher than 1400℃),then cast it into a mold and cooled quickly. After that, the sample was taken out and the surface was polished to a smooth surface for analysis.

The usual method of whitening cast iron:

(1) By increasing the temperature of the casting sample, the supercooling degree of molten iron can be increased, and the inclusion as the graphite core can be avoided and reduced, so as to improve the degree of whiteness. The casting temperature should be above 1400 ℃.

(2) The cooling rate of casting sample block was increased and the cooling condition of cast iron sample block was improved.

(3) The reb-graphite element is added into the molten iron.

The Ruishenbao furnace can fully meet the requirements :

(1) high-frequency induction heating is adopted, and the common temperature can reach 1700;

(2) It is formed by casting and can be cooled quickly;

(3) Open operation, free to add different proportions of ingredients

+86 10-57374441

+86 136 8188 9743

info@ruishenbao.com

Whatsapp:+86 13681889743

Skype:+86 13681889743

Room1006,No.280,ShangZhongXiLu,Xuhui district,ShangHai,200237,P.R.China

+86 10-57374441

+86 136 8188 9743

info@ruishenbao.com

Whatsapp:+86 13681889743

Skype:+86 13681889743

Room1006,No.280,ShangZhongXiLu,Xuhui district,ShangHai,200237,P.R.China